Duration: 1 day

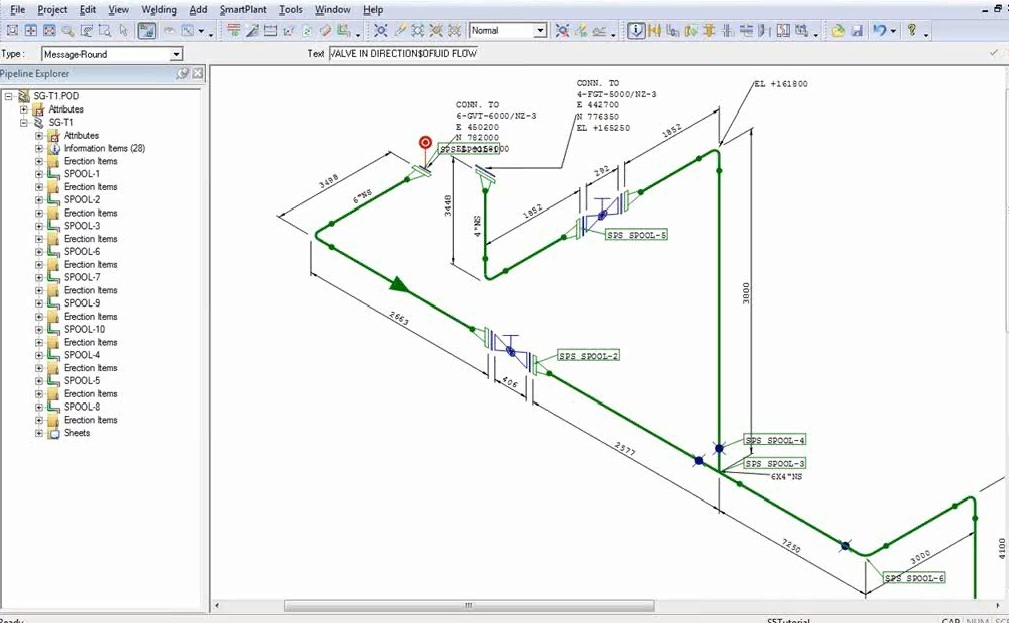

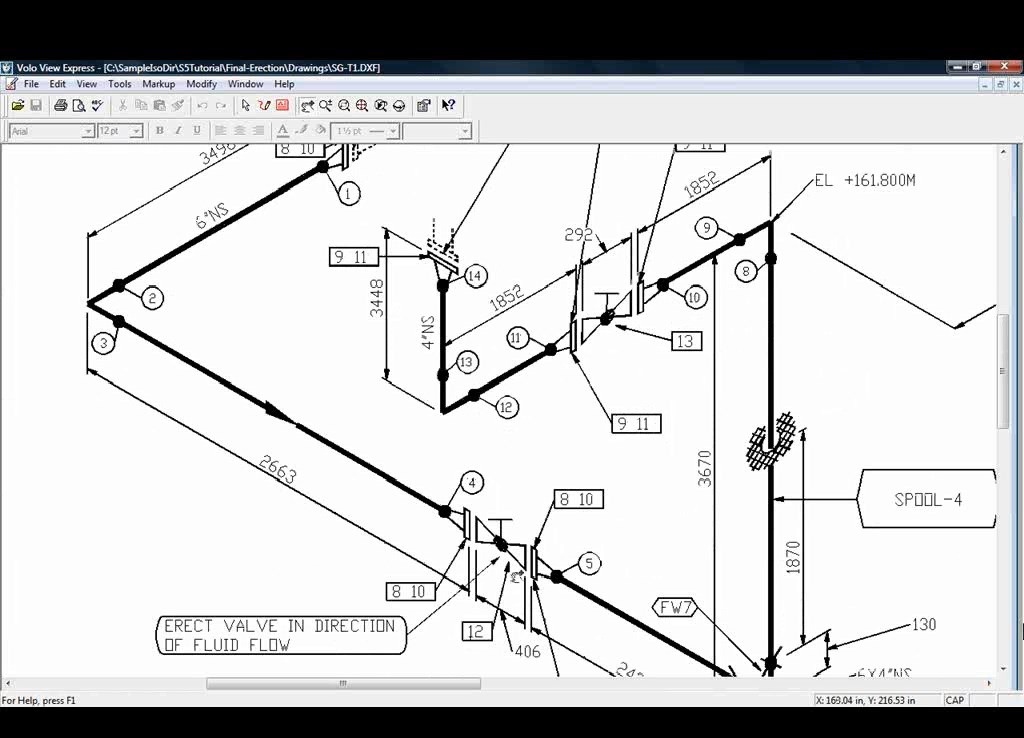

This course provides users with the knowledge and skills to fully operate Spoolgen in order to produce Isometrics and Spool drawings. Spoolgen produces fast and accurate spool and erection isometrics for pipe fabrication and construction. SmartPlantSpoolgen is a proven, industrial-strength application that enables the creation of piping isometric drawings for fabrication and erection from the design created during the detail engineering phase of projects. You can add additional information – such as the location of field welds – and create new drawings and reports from the same source as the original drawings. The technology is based on ISOGEN, the industry-standard software for automated piping isometric generation, and has been deployed successfully on all sizes of plant engineering projects in every region of the world.

Belvej Consulting Limited delivers a classroom lecture and lab format that provides the most practical and efficient hands-on reinforcement in the use of the tools and procedures.

Why Use Spoolgen?

- SmartPlantSpoolgen is fast and accurate because it eliminates the need to redraw isometrics and manually re-create material take-off reports.

- SmartPlantSpoolgen can work with data from almost any plant design system – Intergraph® SmartPlant 3D, PDS®, and CADWorx®; AVEVA PDMS; and Bentley AutoPLANT and PlantSpace are all supported.

- SmartPlantSpoolgen boosts productivity because no CAD skills are needed, yet it uses the ISOGEN engine to create industry-standard, high-quality pipe spool drawings in many different formats – automatically and without drafting.

- Changes to the source data are strictly controlled to maintain design integrity, helping to eliminate transcription errors and ensuring that the design intent is faithfully preserved throughout the fabrication and erection phases.

By the end of the course you will be able to:

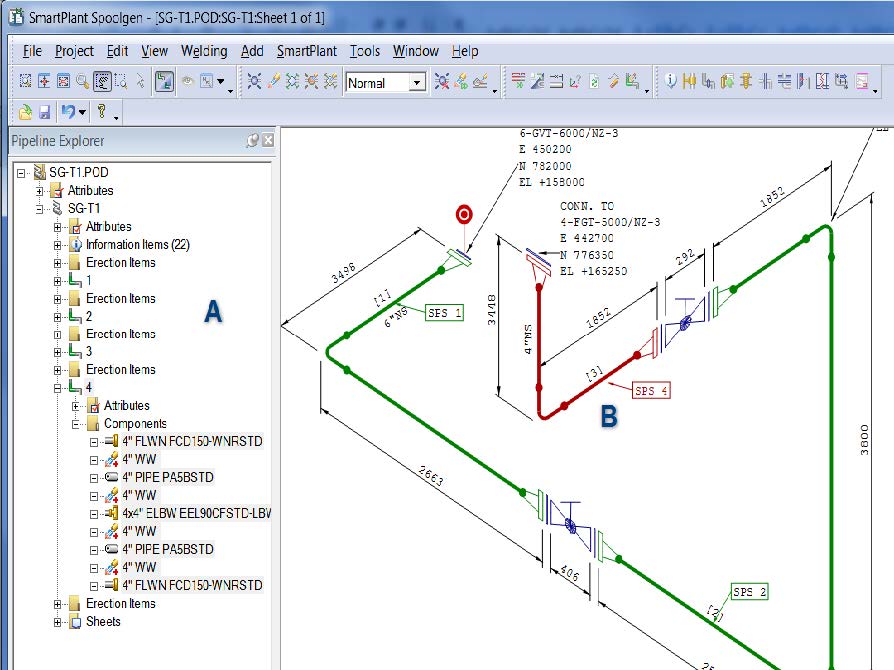

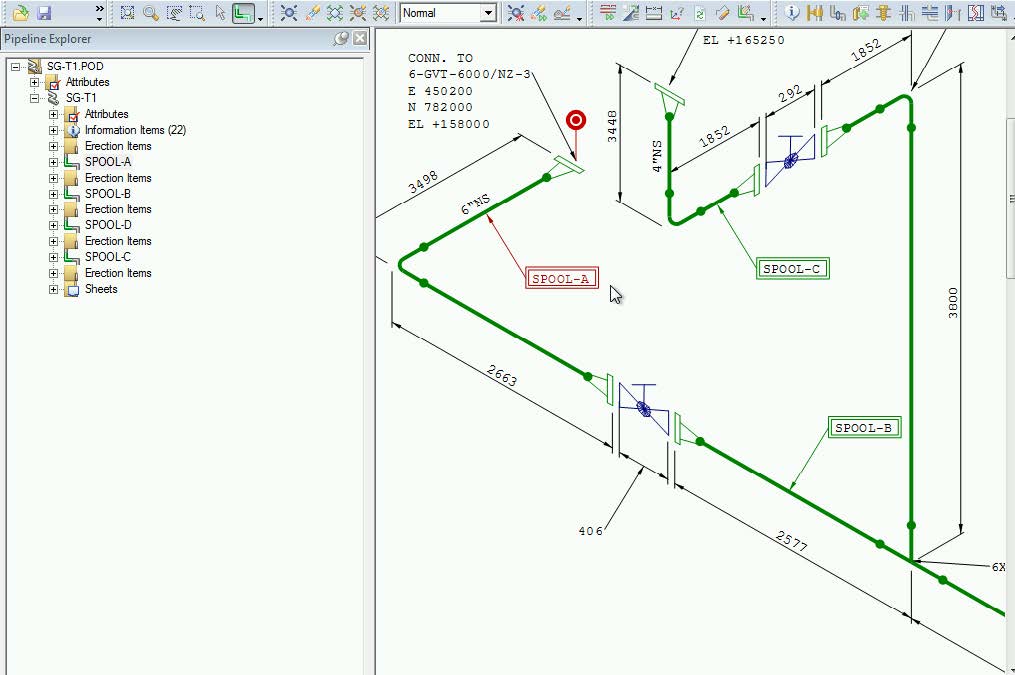

- Create Spools using Spoolgen,

- Place welds and other fabrication and construction information, importing and modifying pipelines, cut and paste, weld and part numbering, weld gaps, elbow to bend conversion, building materials data, project administration,

- Configure drawing and report outputs, creating user symbols, attributes and information,

- Create 3D visualization,

- Generate isometric drawing, linking to external data sources, data integration with downstream systems.

- Understanding the Data Flow

- Spoolgen Interface

- Project Login

- Importing / Checking out / Checking in

- Using the Workflow Database

- Selection techniques

- Multiple selections

- Selecting Spools / Spool naming

- Drawing Split Points

- Adding / Modifying welds

- Generating outputs

- Using the 3D view

- Adding Pipe Supports

- Adding Couplings

- Adding Reference Dimensions

- Adding Additional Materials

- Adding Flow Arrows

- Adding Detail Sketches

- Adding Information Notes

- Adding Component Properties

- Adding Weld Properties

- Adding Elbow to Bend conversion

- Retrieving External Data